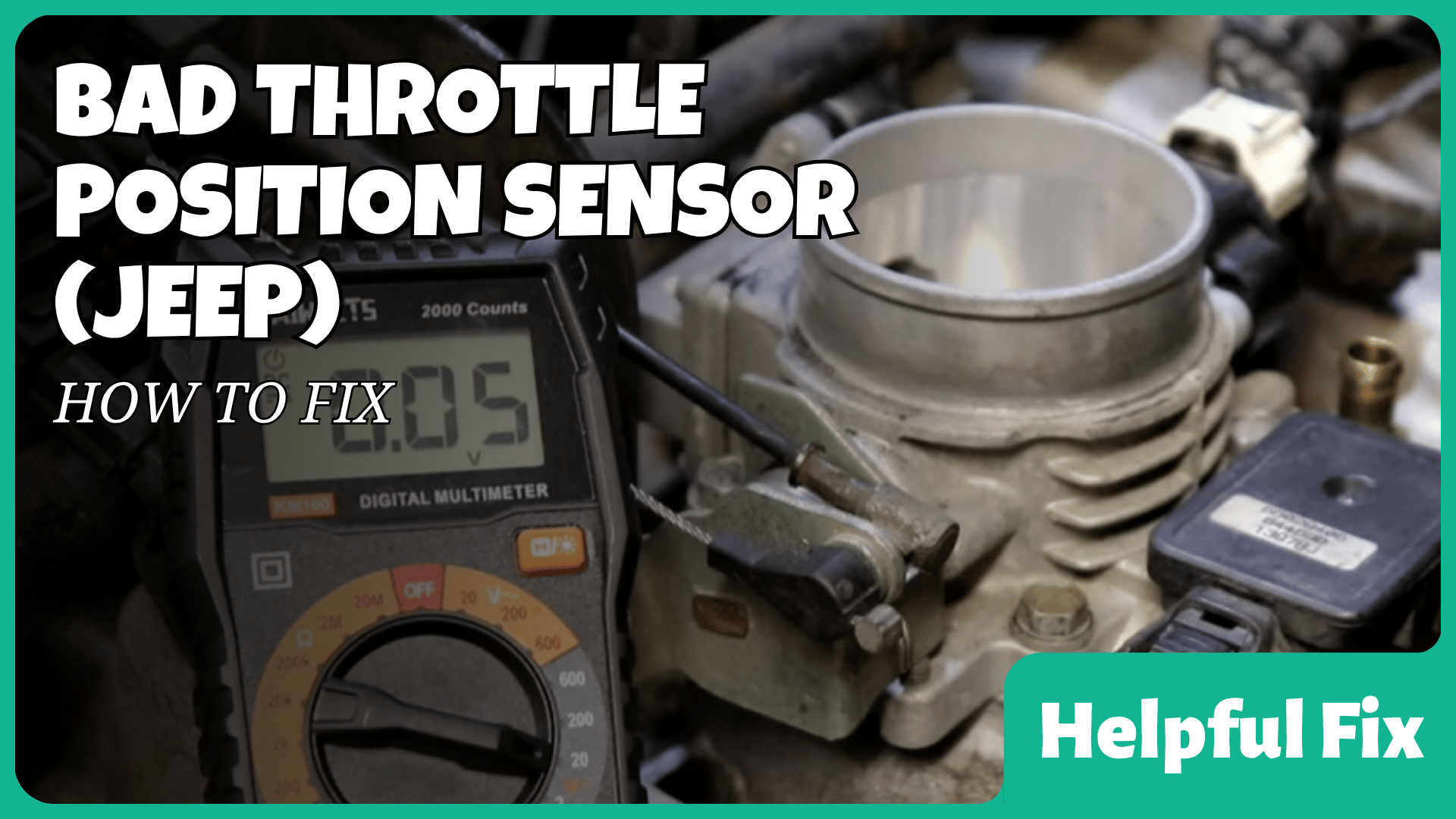

Bad Throttle Position Sensor (TPS) on Jeep – How to Fix

The throttle position sensor causing erratic behavior on a Jeep is fast, visible, and fixable. When the TPS fails it sends incorrect voltage to the engine control module. The result is surging idles, stumbling under load, and unpredictable stalling. This guide focuses on Jeep models most affected, explains exact diagnosis steps, lists every likely failure mode, and gives clear repair and calibration instructions you can follow with basic tools.

Quick summary

- Primary symptoms: idle surge, fluctuating RPM, rough idle, hesitation under acceleration, check engine light with P0121/P0122/P0123 codes.

- Most affected Jeeps: Cherokee XJ and TJ models with the 4.0L are commonly reported as prone to TPS-related issues; check model-specific threads and bulletins before assuming other causes. See an example explanation for Cherokee XJ TPS problems here.

- Quick bench test: three-wire TPS should show ~0.5 V at closed throttle and around 4.2–4.5 V at wide open throttle when the pedal is moved slowly.

- Fast check before replacing: inspect wiring harness and connector for corrosion or broken wires. Back-probe the signal while monitoring voltage and confirm smooth, linear change as the throttle opens.

- If codes present: read and record codes, clear them, then reproduce. Common TPS codes include P0121, P0122, P0123; see a practical diagnostic guide at AutoZone.

- Replacement tip: replace with an OEM or high-quality aftermarket TPS and follow the Jeep-specific calibration or relearn procedure described later.

Common symptoms on a Jeep

- Idle RPM hunting or surging. Engine RPM swings between low and high without driver input. Owners report swings like 800 to 1400 RPM on Cherokee examples.

- Rough idle and stalling. Engine may stall when coming to a stop or at idle in gear.

- Hesitation or bucking under acceleration. Car bucks during throttle application or has delayed response.

- Check Engine Light. Codes related to throttle position appear in the ECU memory.

- Unpredictable cruise control or limp mode activation. The vehicle may enter a reduced-power state while the ECU limits throttle input.

Why Jeeps get TPS problems

Older Jeep platforms use a throttle/body arrangement with a three-wire TPS mounted on the throttle body. Physical wear, contamination, and wiring harness issues are common causes. Carbon buildup on the throttle body changes airflow and exaggerates TPS readout problems. Forums and owner reports for Cherokee and TJ models document repeated TPS failures and symptom patterns, making these vehicles useful case studies for troubleshooting: TJ owner experiences and a real-world Cherokee example shown on video.

How the TPS works (brief)

Most TPS units on Jeeps are three-wire potentiometers. One wire receives a regulated 5 V reference from the ECU. One is ground. The third is the signal that varies between ~0.5 V at closed throttle and ~4.5 V at wide open throttle. The ECU reads that voltage to control fuel delivery, ignition timing, and idle control. When the signal is noisy, intermittent, or out of expected range the ECU uses stored logic that can cause stalling or reduced power.

Diagnosis: step-by-step

Tools required

- OBD-II scanner (capable of live data if possible)

- Digital multimeter

- Basic hand tools to access the TPS

- Back-probing pins or paperclips

Step 1 — Read and record codes

Connect a scanner and capture trouble codes and freeze-frame data. Note codes with P0120-series numbers. Clear codes after recording and attempt to reproduce the symptom. Persistent reappearance confirms an active issue. If you are unfamiliar with reading DTCs, follow the diagnostic methods outlined by AutoZone.

Step 2 — Visual inspection

Inspect the TPS connector, wiring harness, and mounting screws. Look for chafed wiring, melted insulation, or oil contamination. Wiggle the harness while key-on engine-off and note any changes in readings during live data monitoring.

Step 3 — Voltage testing

- Back-probe the connector: identify reference (5 V), ground, and signal wire. With key-on engine-off the reference should read ~5 V to ground.

- Measure the signal voltage at closed throttle. Expect approximately 0.4–0.8 V closed. Slowly open the throttle while watching signal voltage. It should increase smoothly to about 4.2–4.5 V at wide open throttle. Any sudden jumps, drops, or noisy spikes indicate a failing TPS.

- If the reference or ground is missing or intermittent, repair wiring instead of replacing the sensor.

Step 4 — Compare live data

Use a scan tool to watch throttle position percentage and sensor voltage while working the throttle. The displayed values should change smoothly and proportionally. Jerky or jumping numbers are a fault. If you cannot get live data, use the multimeter as described.

Step 5 — Inspect the throttle body

Remove and inspect the throttle plate and bore. Heavy carbon and deposits can cause the throttle plate to hang slightly or provide inconsistent mechanical movement. Clean the throttle body with a suitable throttle-body cleaner before condemning the TPS.

Common failure modes and how to check each

- Worn potentiometer: noisy or inconsistent voltage during throttle sweep. Replace TPS after confirming wiring is good.

- Connector corrosion: intermittent contacts cause random surges. Clean or replace connector pins and use dielectric grease.

- Broken ground or 5 V feed: the sensor cannot produce correct output. Test supply and ground; repair harness if faulty.

- Mechanical binding: throttle shaft wear or gunked throttle body prevents linear movement. Clean and lubricate moving parts; replace if shaft is loose.

- ECU interpretation error: rare but possible. If two TPS units were tested and wiring is good, ECU inputs may be suspect; consult a shop.

Repair and replacement: step-by-step

Parts

Choose OEM or high-quality aftermarket TPS. For classic Jeep models replace with a unit specified for your year and engine. If available, compare part numbers and resistances.

Tools and time

Basic hand tools. Typical job time: 30–90 minutes depending on access and throttle-body cleaning.

Replacement steps

- Disconnect the negative battery terminal.

- Remove the air intake duct to access the throttle body and TPS connector.

- Unplug electrical connector and back-probe to confirm readings before removal for verification.

- Remove mounting screws. Note TPS orientation to preserve shaft alignment.

- Install new sensor in the same orientation. Do not force the shaft. Tighten screws to proper torque.

- Reconnect connector and intake. Reconnect battery.

- Perform TPS calibration or throttle relearn if required by the model. Some Jeeps require a simple key-on idle sequence, others use a scan tool; see calibration below.

Calibration and relearn

Certain Jeep models require the throttle position sensor to be calibrated. Procedures vary by year. Common methods include turning the key to ON for a set time with throttle closed, or using a scan tool to run an ECU relearn routine. If you do not have the exact procedure for your Jeep, run the basic steps: start the engine, let it reach operating temperature with no accessories on, allow idle to stabilize for 2 to 5 minutes, and cycle accessories to confirm stable idle. If problems persist after replacement consult model-specific service literature or a scan tool-based relearn.

Preventive maintenance

- Keep the throttle body clean. Heavy carbon accelerates wear and causes erratic readings.

- Inspect the TPS connector during routine service for corrosion and secure fit.

- Use dielectric grease on connectors when reassembling to slow corrosion.

- Address check engine codes early to avoid ECU compensations that mask the root cause.

Cost and parts guidance

Typical TPS part costs range from moderate to high depending on OEM vs aftermarket. Expect DIY total cost including sensor to be under $200 for most Jeeps. Labor at a shop is low because the job is quick, but diagnostic fees raise the bill if intermittent wiring faults are present. Always compare part numbers and confirm compatibility with year, engine, and throttle body configuration.

DIY vs professional repair

Replaceable sensors and straightforward voltage tests make TPS work a good DIY job for anyone comfortable with tools and diagnostics. If wiring faults, intermittent connector issues, or ECU-level problems are suspected, get professional diagnostics. Intermittent electrical faults can be time-consuming without proper shop equipment.

Frequently Asked Questions

How can I tell if the TPS or the ECU is bad?

Start by validating wiring and sensor voltages. If the TPS voltage is smooth and within expected ranges but the ECU reports incorrect values, the ECU may be at fault. Swap in a known-good TPS and recheck. If the problem persists with good wiring and a known-good sensor, have the ECU tested at a shop.

What voltage should the TPS read at idle for my Jeep?

At closed throttle expect roughly 0.4–0.8 V. At wide open throttle expect about 4.2–4.5 V. Values outside those ranges or a signal that jumps or drops indicate a problem.

Will cleaning the throttle body fix TPS symptoms?

Cleaning often helps when carbon causes the throttle plate to stick or move inconsistently. However cleaning only helps if the sensor itself and the wiring are healthy. Always confirm TPS output after cleaning to determine if replacement is still necessary.

Can a bad TPS cause the check engine light to flash?

Yes. A failing TPS can produce stored trouble codes and illuminate the check engine light. Flashing lights often indicate misfire conditions. Address the underlying issue promptly.

Do modern Jeeps use throttle-by-wire and how does that change troubleshooting?

Newer Jeeps with electronic throttle control have a different architecture. They use pedal position sensors and throttle body sensors in combination. Troubleshooting requires reading multiple sensor inputs and may need manufacturer-specific relearn procedures. Refer to model-specific documentation in those cases.

Which diagnostic codes point to a bad TPS?

Common codes include P0120 series codes such as P0121, P0122, and P0123 related to throttle position sensor range and performance. Use an OBD-II scanner to read and clear codes and monitor live data for confirmation as a reference.

Where can I find Jeep-specific discussions and real-world failures?

Owner forums and model-specific blogs provide many real-world cases and fixes for Cherokee XJ and TJ models. For Jeep TJ owner experiences see forum threads documenting TPS failures here. For a video showing a Cherokee example with RPM fluctuations check out this.

Will replacing the TPS stop limp mode?

If limp mode was triggered by a faulty TPS and no other faults exist, replacing and recalibrating the TPS will clear the condition. If limp mode continues, further diagnostics are required to find other issues.

Fix a bad TPS on a Jeep with methodical testing, not guesswork. Verify voltages, clean the throttle body, inspect wiring, and only then replace the sensor. Follow with the proper relearn or calibration and the Jeep will return to predictable operation.