Jeep Grand Cherokee Won’t Move in Gear (How to Fix)

If your Jeep Grand Cherokee refuses to move when placed in Drive or Reverse, you face a transmission or driveline failure that can be simple to fix or expensive. This guide lists every common cause, how to test for each problem, step-by-step fixes you can attempt, repair and parts expectations, and clear advice on when to tow the vehicle. Use the diagnostics in the order shown to narrow down the cause fast.

Quick summary

- Check fluid first: low, contaminated, or burnt transmission fluid is the most common user-serviceable cause.

- Scan for codes: an OBD2 scan often points to solenoid, sensor, or control module faults.

- Electronic shifter and interlock: known issues can leave the Jeep stuck in Park or prevent engagement.

- PTU and mechanical failures: internal Power Transfer Unit problems can disengage the drivetrain entirely.

- Valve body, torque converter, or mount damage: these require professional repair or transmission rebuild.

- Don’t drive if you have loss of drive while moving: that is unsafe and can worsen internal damage.

Common causes and how to check and fix them

1. Transmission fluid level or contamination

Why it stops the vehicle: Low fluid or burnt fluid prevents hydraulic pressure from building, which stops clutches and gearsets from engaging.

How to check:

- Warm the engine to operating temperature, park on level ground, and check the transmission dipstick per the owner’s manual.

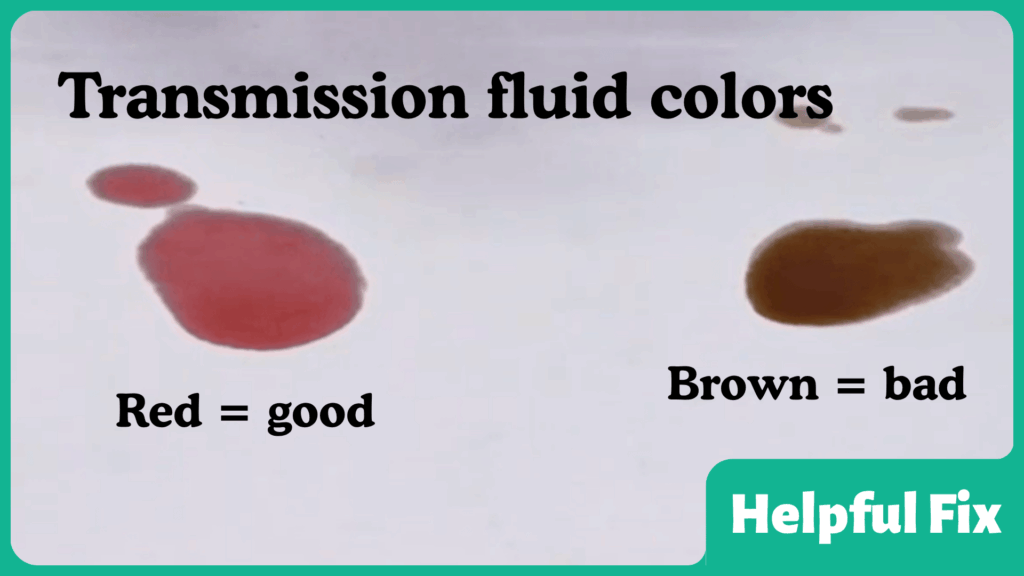

- Smell and inspect the fluid color. Healthy fluid is red. Brown or black fluid with a burnt odor indicates overheating and contamination.

How to fix:

- Top up with the manufacturer-specified fluid only if low. Do not mix fluid types.

- If fluid is dirty or burnt, perform a fluid change and filter service. If fluid is severely burnt or metal is present, plan for transmission inspection or rebuild.

Sources link this as a primary diagnostic and repair step: see guidance on common transmission checks and remedies at NewParts and routine fluid care tips at The Land Auto Repair.

2. Electronic shifter problems and shift interlock solenoid

Why it stops the vehicle: The electronic shifter or the brake-transmission shift interlock solenoid can fail, leaving the transmission mechanically disconnected or the shifter stuck in Park.

How to check:

- Try the manual shift release procedure in the owner’s manual. If the shifter will not move even with the release, the interlock solenoid or the shifter assembly may be faulty.

- Scan for transmission and body control module codes related to the shifter or solenoid.

How to fix:

- Replace the shift interlock solenoid or the shifter assembly if codes and tests confirm failure.

- For certain model years there are documented design recalls and service bulletins addressing stuck-shifter problems; verify recalls for your VIN when applicable.

Recall and reliability reporting point to this as an intermittent but critical failure mode for some Grand Cherokee model years. See reporting on reliability and the brake-shift interlock recall at CarParts.

3. PTU (Power Transfer Unit) or transfer case input problems

Why it stops the vehicle: If the input shaft or internal ring gear in the PTU is not seated or it fails, power may not be transferred from the transmission to the driveline. Vehicles with this fault may not go into Drive or may lose drive while moving.

How to check:

- If the engine revs normally when you press the accelerator but the vehicle does not move, suspect PTU or internal transmission disengagement.

- Scan for codes and listen for grinding or abnormal noises when shifting into gear.

How to fix:

- PTU or internal transmission repairs require drop and inspection. Replacement or reassembly is often needed.

- Check if your model has an affected recall or service action; manufacturers sometimes issue fixes for seating issues.

Consumer Reports documented a recall and safety action related to input shaft seating problems that can cause drive disengagement on some Jeep models.

4. Valve body, solenoids, and electronic control faults

Why it stops the vehicle: The valve body directs fluid to clutch packs. Solenoid failures or valve body damage prevent correct gear application and can make the vehicle fail to move.

How to check:

- OBD2 codes related to shift solenoids, pressure sensors, TCM (transmission control module) errors, or hydraulic faults indicate valve body or solenoid issues.

- Symptoms include no engagement, harsh or delayed shifts, and limp-home mode.

How to fix:

- Replace faulty solenoids, or rebuild/replace the valve body. In some cases, a software update to the TCM (dealer reflash) resolves odd electronic shifting behavior.

5. Torque converter failure

Why it stops the vehicle: A failed torque converter will not transfer engine torque into the transmission, producing engine revs without vehicle movement.

How to check:

- With the transmission in Drive and foot on the brake, slightly rev the engine. If RPM jumps but the vehicle does not attempt to move, the torque converter may be slipping or disconnected internally.

- Scan for codes and listen for abnormal noises at the converter area.

How to fix:

- Torque converter replacement is required. This is a labor-intensive repair because the transmission typically must be removed.

6. Transmission mounts, linkage, and mechanical damage

Why it stops the vehicle: Broken mounts or linkage prevent proper alignment and engagement. Additionally, prior misuse like forcing low-range changes can mechanically damage gears.

How to check:

- Visually inspect mounts and linkage for broken rubber, loose bolts, or disconnected rods.

- If the vehicle was making grinding noises or you experienced violent jerks before the failure, expect internal damage.

How to fix:

- Replace damaged mounts or linkage. If internal damage exists, a transmission teardown is required.

Step-by-step diagnostic checklist (work down this list)

- Park safely and verify the symptom: With parking brake on and engine running, move the shifter to Drive and Reverse while a helper watches wheel movement. Note whether engine revs and whether wheels try to turn.

- Scan for codes: Use an OBD2 scanner that reads transmission and body codes. Save or photograph codes and freeze-frame data.

- Check fluid: Inspect level, color, and smell. Top off only if low and use the correct fluid type. If fluid is burnt or contaminated, plan a filter and fluid change.

- Test electrical and fuses: Inspect transmission-related fuses and wiring connectors for corrosion or detached plugs.

- Perform shift linkage and interlock checks: Try manual shift release and inspect shifter assembly for play or binding.

- Assess torque converter engagement: Slightly rev engine in Drive with brake held. If RPM jumps without load, suspect the converter.

- Listen for unusual noises while shifting: Grinding, clunks, or whines indicate internal damage requiring teardown.

- Consult service bulletins and recalls: Compare symptoms and VIN against known manufacturer actions and recalls. Manufacturer fixes can save money versus replacement.

- If unsure, tow to a reputable transmission shop: Driving with no drive or intermittent drive will cause more internal damage and higher repair cost.

Repair options and cost expectations

- Fluid and filter service: $150 to $400. Effective if the issue is fluid-related or solenoid contamination.

- Solenoid or valve body repair: $400 to $1,500. Costs vary by parts and whether a valve body reprogram is required.

- Torque converter replacement: $800 to $2,000 depending on labor and part source.

- Transmission rebuild or replacement: $2,000 to $6,000 or more. Rebuilds are worthwhile when multiple internal components are damaged.

- Shifter assembly or interlock solenoid repair: $150 to $800 depending on part and labor.

When to tow and when you can drive

- Tow now: If the vehicle loses drive while moving, has grinding noises, or fluid is burnt with metal shavings present. Driving risks catastrophic internal damage.

- Safe to move short distances: If the only issue is a low fluid level that you can top up and there are no unusual noises. Still proceed cautiously and get a full inspection immediately.

Frequently Asked Questions

Why does my Grand Cherokee rev but not move?

If the engine revs and wheels do not respond, first check that you aren’t in neutral gear. If you aren’t, then the torque converter may have failed, the transmission may be mechanically disengaged, or the PTU may not be transmitting power. Confirm by checking fluid level, scanning for transmission codes, and testing for torque converter slip.

Could a simple fluid change fix it?

Yes. If the only fault is low, burnt, or contaminated fluid affecting hydraulic pressure, a fluid and filter change can restore operation. If metal particles or severe burning are present, a fluid change will not be sufficient.

How do I know if the shifter is faulty or the transmission is bad?

Use the manual shift release and an OBD2 scan. If the shifter will not move despite manual release or if codes indicate body control or shift interlock faults, the shifter assembly or solenoid is likely at fault. If the shifter moves but the vehicle does not engage, the transmission or torque converter is the suspect.

Are there known recalls or model-year problems I should check?

Yes. Some Jeep models had recalls and service actions for shift interlock and PTU input shaft seating problems. Always check your VIN against manufacturer recalls and service bulletins. Manufacturer actions can be the least expensive fix option; verify eligibility before paying for repairs.

Can I drive to a shop if the Jeep sometimes moves and sometimes does not?

Only if you can safely reach a nearby shop without further damaging the transmission. Intermittent engagement often precedes complete failure. When possible, tow the vehicle to avoid escalating repair costs.

What diagnostic tools should I have or request?

Use a full-function OBD2 scanner with transmission code capability, a transmission fluid pressure gauge for advanced diagnosis, and a helper to observe wheel behavior. Transmission shops will also perform road-force tests and pan inspections for metal contamination.

How long do common repairs take?

Fluid and filter service: a few hours. Solenoid or valve body work: one day to two days. Torque converter or full transmission replacement: two to five days depending on parts availability and shop workload.

Is it worth rebuilding an older transmission?

Consider rebuild if repair costs are significantly less than replacement and the vehicle condition justifies it. For high-mileage vehicles with repeated failures, replacement or a salvage transmission may be the better value.

Where can I find parts and reliable repair guidance?

Use OEM or high-quality aftermarket parts and choose a shop with transmission specialization. Independent transmission shops often provide better diagnostic depth than general repair shops.

What preventive maintenance reduces the chance of this issue?

Regular transmission fluid checks and changes, avoiding aggressive towing beyond vehicle limits, and addressing shift anomalies early will reduce the risk of a no-drive failure. Inspect mounts and linkage routinely.