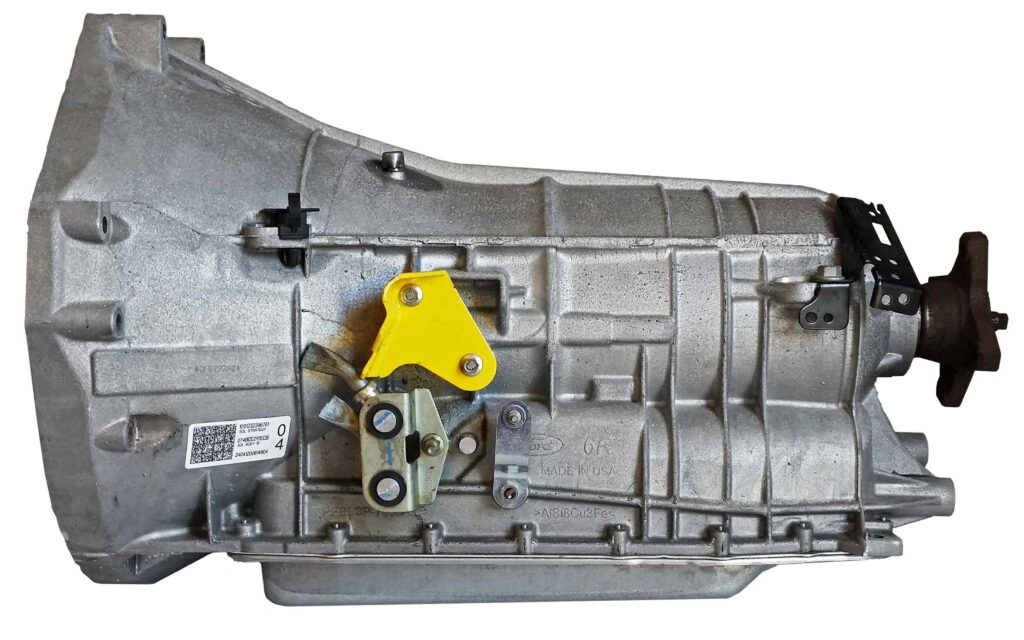

6R80 Transmission Problems and How to Fix: Complete Guide

Based on widespread user feedback and mechanic reports, the most frequent 6R80 problems typically revolve around overheating, delayed shifting, harsh shifting, and gear slippage—all of which were covered in the previous article. However, there are a few additional issues and considerations worth mentioning when discussing the 6R80.

1. Molded Lead Frame or Sensor Failures

On some 6R80-equipped vehicles (particularly 2011–2012 F-150s), the transmission’s molded lead frame and its internal sensors can fail. When this happens:

- The transmission might default to a “limp” mode or show irregular shifting patterns.

- You may see diagnostic trouble codes (DTCs) relating to the transmission output speed sensor or shaft speed sensor.

- Ford issued Technical Service Bulletins (TSBs) and, in some cases, recalls to address this issue.

How to Address

- Check for error codes (P0720, P0722, etc.) with a scan tool.

- If codes persist or shifting anomalies remain, replacing the lead frame assembly may be necessary.

- Seek a Ford dealership or reputable transmission shop experienced with 6R80 repairs.

2. Shift Solenoid Issues

The 6R80 relies on electronic solenoids to regulate fluid flow and pressure for gear changes. Over time or under extreme conditions, solenoids can:

- Become clogged or gummed up due to contaminated fluid.

- Wear out electrically, leading to inconsistent or unpredictable shifts.

How to Address

- Perform a diagnostic scan to check for solenoid-specific DTCs (e.g., P07xx series).

- If a solenoid is failing, it might need cleaning, rebuilding, or replacement.

- A fluid flush or pan drop with filter replacement can help prevent future clogging.

3. Fluid Pump or Valve Body Wear

Though less common, the front fluid pump or the valve body can exhibit wear in higher-mileage 6R80s or those under heavy towing/hauling conditions. Symptoms often overlap with harsh or delayed shifting:

- Low line pressure can cause delayed engagement, neutral-like conditions between shifts, or slip.

- Valve body bores or gaskets can wear out, leading to pressure leaks.

How to Address

- Perform a pressure test to confirm fluid pump performance.

- Inspect or rebuild the valve body (including the separator plate, gaskets, and any worn accumulators).

- Replace any damaged components, such as the pump gears or valve body sleeves.

4. “Clunk” During Downshifts or Engagement

Some owners report a noticeable “clunk” or harsh engagement during certain gear changes (especially downshifting into 1st). Possible culprits:

- Excessive driveline backlash.

- Worn universal joints (U-joints) or rear differential components.

- Damaged or worn output shaft splines in extreme cases.

How to Address

- Check for worn U-joints or driveshaft play.

- Inspect differential bushings and mounts for excessive movement.

- If driveline checks out, inspect the transmission output shaft or extension housing for wear.

5. Preventive Maintenance & Best Practices

Even if your 6R80 is running smoothly, taking proactive steps will help minimize future problems:

- Regular Fluid Changes

- Ford generally recommends fluid checks/changes around 30,000-mile intervals under severe use (towing, off-roading).

- Use the manufacturer-recommended Mercon LV transmission fluid.

- Monitor Temperatures

- If you frequently tow or drive in hot climates, consider an upgraded transmission cooler.

- Install a transmission temperature gauge or monitor it through an OBD-II device if possible.

- Firmware Updates

- Some shifting quirks can be addressed by an updated TCM (Transmission Control Module) calibration.

- A dealership can reflash your transmission computer with the latest software, if applicable.

6. When to Seek Professional Help

Basic checks—like monitoring fluid levels, scanning for codes, and following reset procedures—can be done at home. However, if you experience:

- Persistent or severe slipping and flares.

- Unusual grinding, whining, or knocking noises.

- Multiple error codes or limp mode that resets but keeps coming back.

…it’s best to contact a qualified transmission specialist or Ford dealership. Early, accurate diagnosis can prevent more extensive (and expensive) damage.

In Summary

The 4 major issues (overheating, delayed shifting, harsh shifting, and gear slippage) remain the most commonly reported troubles for the 6R80. Beyond those, molded lead frame failures, shift solenoid issues, potential valve body wear, and driveline “clunk” can also arise.

When properly maintained with routine fluid changes and cooling measures—and updated as needed with TCM firmware—this transmission typically performs well. Should deeper mechanical problems appear, a specialist well-versed in 6R80 repairs can often restore its reliability.

Disclaimer: This guide offers general information and does not replace professional diagnosis. Always refer to official Ford documentation or consult a certified mechanic for specific repair procedures.