Jeep 2.0 Turbo Problems (Troubleshooting Guide)

The Jeep 2.0L Hurricane Turbo powers the Wrangler with strong low‑end torque but comes with a mixed track record. This guide compiles the most credible, practical information about common problems, how to check for them, and the best steps to fix or mitigate failures. It draws from owner reports, technical discussions, and the latest consumer-facing testing to help you diagnose, plan maintenance, and decide when to seek service or upgrades.

Quick summary

- Turbocharger health matters: expect turbo lag, boost fluctuations, and possible early wear. Inspect hoses and leaks first.

- Oil consumption and leaks: monitor oil level regularly; look for leaks around the pan and turbo lines.

- Coolant system integrity: watch for leaks near the water pump and reservoir; overheating can accelerate wear.

- Direct‑injection carbon buildup: intake valve deposits can reduce performance; consider cleaning if symptoms appear.

- Piston failure risk: rare but reported at relatively low miles in some cases, often linked to high‑stress operation; octane and oil quality matter.

- Sensors and emissions systems: check engine light and EGR issues can trigger limp mode if faults exist.

- Cooling and maintenance discipline: turbo life improves with proper cooling cycles and adherence to service intervals.

- Real‑world reliability is mixed: owners describe mediocre long‑term reliability relative to expectations, especially as miles accumulate.

- Engine choice tradeoffs: the 2.0T delivers torque but often lags in throttle response versus the V6; some buyers value torque others prefer immediacy.

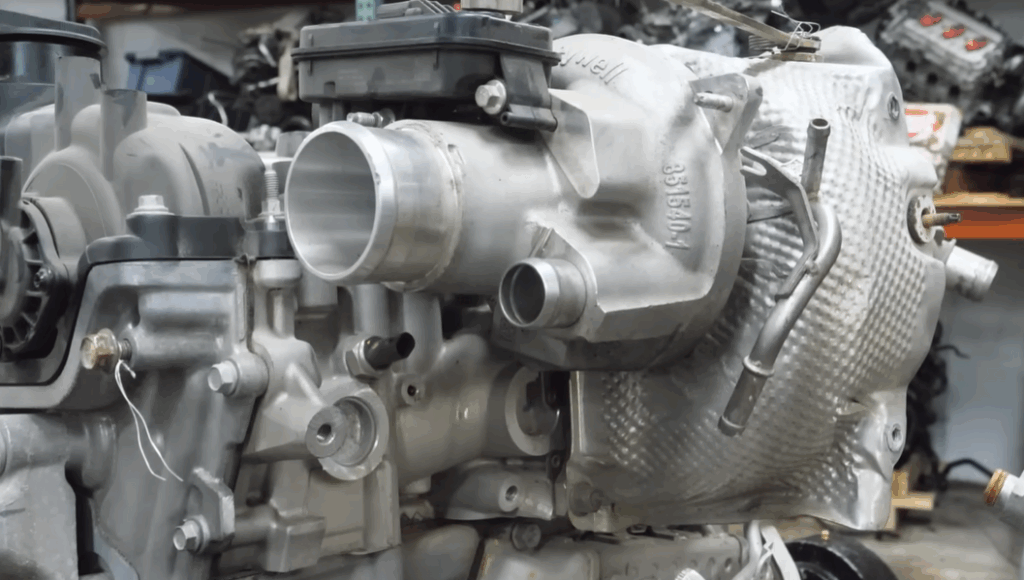

Turbocharger health and boost performance

Symptoms to watch

Turbocharger problems manifest as lag before boost, inconsistent boost pressure, and delayed spooling. Listen for unusual whines or flutter from the turbo area, and note any sudden drops in acceleration that don’t match engine speed.

What causes it

Root causes include internal wear in the turbo cartridge, worn boost control components, and boost leaks in hoses and clamps. A common thread in owner discussions is that turbo life heavily depends on proper cooling and maintenance. See discussions noting boost leaks from worn hoses and the impact of fuel quality on turbo life.

How to check

- Perform a visual inspection of all turbo feed and return lines for cracks, leaks, or loose connections.

- Scan for codes related to boost pressure or pressure sensor faults and monitor live boost data with a compatible tool.

- Check for oil leaks around the turbo housing and associated lines; inspect for oil contamination in the intercooler piping.

- Test boost response on a controlled pull; compare target boost values to actual readings at various rpm.

Step‑by‑step fixes

- Repair boost leaks: replace worn hoses, clamps, or piping, and reseal intercooler connections as needed.

- Replace faulty boost control components if a sensor or valve is malfunctioning; update or reset electronic control if required.

- Ensure clean oil delivery: perform an oil and filter change with the manufacturer‑recommended oil grade and viscosity; inspect oil lines for blockages or kinks.

- Address turbo wear: if the cartridge shows excessive play or noisy operation, a professional replacement or remanufactured unit may be required.

- Support cooling: verify the cooling system is functioning, bleed air properly after service, and maintain coolant at the correct level to prevent turbo overheating.

For context, long‑term owner discussions emphasize that turbo life depends on cooling and maintenance, including avoiding boost leaks that degrade performance over time. Forum threads on reliability highlight this dynamic.

Oil consumption and oil leaks

Symptoms

Excessive oil consumption or visible oil spots under the vehicle are common signals. Small leaks around the oil pan or turbo oil lines also appear in user reports.

What causes it

Poor sealing surfaces, degraded gaskets, or failing PCV components can increase oil leakage. Increased oil usage can be tied to turbo lubrication demands and engine stress under boost.

How to check

- Record oil consumption over a defined distance (e.g., 1,000 miles) and compare to the manufacturer’s baseline.

- Inspect the oil pan gasket, turbo oil lines, and valve covers for seepage.

- Check PCV valve operation and hoses for cracks or blockages.

Step‑by‑step fixes

- Replace leaking gaskets and seals, including the oil pan gasket and turbo oil lines as needed.

- Replace PCV components if valve sticking or hose collapse is detected.

- Confirm oil quality and grade; perform an oil change with the correct specification and use a high‑quality filter.

- Recheck for leaks after service and monitor oil consumption to ensure resolution.

These issues are cited as common reasons owners turn to extended coverage and service plans, especially after the factory warranty ends.

Coolant system integrity

Symptoms

Unexplained coolant loss, visible dampness around the water pump or reservoir, or overheating events signal cooling system trouble.

What causes it

Leaks frequently originate near the water pump, coolant reservoir, or associated hoses. A failing water pump or cracked reservoir can cascade into overheating and accelerated wear on the turbo and engine.

How to check

- Perform a pressure test on the cooling system to locate leaks.

- Inspect the reservoir cap, hoses, and water pump for signs of seepage or cracks.

- Monitor coolant temperature and ensure fans engage properly at normal operation.

Step‑by‑step fixes

- Replace any leaking hoses, the reservoir, or the water pump as indicated by the diagnostic findings.

- Bleed the cooling system to remove trapped air after service; refill with the correct coolant mixture and brand.

- Verify that the radiator and cooling fans are functioning and not obstructed by debris.

Maintaining the cooling system is repeatedly cited as a key factor in extending turbo life and overall reliability, reinforcing the mantra to follow scheduled service and monitor for leaks.

Carbon buildup from direct injection

Symptoms

Direct injection can lead to intake valve carbon deposits that reduce air flow and performance. Symptoms include rough idle, reduced low‑end torque, and occasional misfires.

What causes it

Direct injection delivers fuel directly into the cylinder, leaving the intake valves less cleaned by fuel wash. Over time deposits accumulate on the intake valves and can affect engine breathing and efficiency.

How to check

- Observe idle quality and misfire history through a scan tool.

- In severe cases, perform a valley inspection or valve cleaning evaluation when service access is available.

Step‑by‑step fixes

- Clean intake valves using industry‑standard methods such as walnut blasting if deposits are present.

- Address any associated fuel trim or misfire codes with necessary repairs.

- Schedule regular maintenance with the correct fuel and oil practices to minimize recurrence.

The carbon buildup issue is a consistently discussed factor in Honeycomb direct‑injection engines and is often addressed during major service intervals or when symptoms appear.

Piston failures and low speed pre‑ignition (LSPI) risk

Symptoms and signs

Piston failure has been reported in a Jeep 2.0L Turbo after relatively modest mileages. A notable case described a death of the engine at 63,000 miles attributed to broken pistons. Low speed pre‑ignition is highlighted as a contributing phenomenon in turbocharged engines, particularly under certain operating conditions.

What causes it

LSPI is a high‑risk pre‑ignition event that can occur in turbocharged engines when temperatures and pressures align unfavorably. The engine is designed for 87 octane fuel in many markets, but there are nuanced oil requirements and calibration factors that influence how robustly the engine handles boost and fuel timing.

How to check

- Run a compression test and a leak‑down test if you hear knocking, misfires, or loss of power under boost.

- Review maintenance history for signs of improper octane use, late or skipped oil changes, or degraded oil quality.

- Inspect for abnormal bearing wear or piston damage during any major engine service.

Step‑by‑step fixes

- If piston damage is confirmed, a major repair or engine replacement may be required, depending on severity and warranty coverage.

- Use the recommended octane and oil specifications; avoid sustained high‑boost driving patterns that raise detonation risk.

- Update PCM calibration or perform service campaigns if a defect is acknowledged by the manufacturer.

A published report shows piston failure as a real risk with some 2.0L Turbo engines. It underscores the importance of maintaining fuel quality and oil integrity to mitigate LSPI risk.

Check Engine Light, sensors, and emissions control

Symptoms

Illuminated CELs, misfire codes, EGR faults, or limp‑home mode can appear when sensors or the EGR system falter. These alarms often warn of underlying fuel, air, or exhaust management issues.

What causes it

Sensor faults, EGR valve problems, or emissions control defects can trigger warning lights. In some cases these codes point to a deeper issue in the turbo system, fuel delivery, or carbon buildup.

How to check

- Scan the ECU with an OBD‑II tool to capture fault codes.

- Inspect related components: EGR valve operation, vacuum lines, and intake system sensors.

- Investigate potential sensor faults or software calibration updates from the dealer.

Step‑by‑step fixes

- Replace faulty sensors or EGR valve as indicated by codes.

- Perform a software update or re‑flash if a known calibration issue is detected.

- Address root causes such as turbo leaks or carbon buildup that may trigger secondary faults.

CEL and emissions issues are a frequent maintenance consideration and are often resolved with targeted component replacements and software updates.

Reliability and maintenance context

What owners report

Across community forums and reviews, the 2.0T reliability is described as mediocre over the long term, especially as mileage climbs. The consensus emphasizes proactive cooling, regular maintenance, and paying attention to turbo health to keep the engine performing well.

Comparison with other powertrains

Comparisons show the 2.0T delivers strong low‑end torque but can lag in immediate throttle response versus a naturally aspirated V6. The tradeoff is clear: more torque at low revs versus instant throttle feel. For many buyers, the decision hinges on how they use the vehicle and how much priority they place on sporty responsiveness versus peak torque.

Industry observations note that reliability is mixed between the 2.0T and the 3.6L V6, with neither option universally superior in all scenarios. Regular maintenance and a cautious approach to boost management remain the best defense against early wear.

In practice, the 2.0L Turbo is part of a three‑engine lineup that includes the 3.6L Pentastar V6 and the 6.4L Hemi V8, with some observers calling the trio options that offer varying blends of power, efficiency, and refinement. YouTube reviews and producer discussions summarize these tradeoffs for buyers evaluating 2025 models.

Frequently Asked Questions

What are the most common 2.0L Hurricane Turbo problems?

Turbocharger wear and boost control issues, carbon buildup from direct injection, coolant leaks near the water pump or reservoir, oil consumption or leaks, and check engine light related faults are the main categories cited by sources. See consumer coverage discussions for specifics.

How can I tell if my turbo is failing?

Look for persistent turbo lag, erratic boost pressure, unusual whines or fluttering, and oil leaks around the turbo housing. A diagnostic scan should show abnormal boost sensor or actuator codes.

What maintenance helps prevent turbo problems?

Follow the factory maintenance schedule precisely. Use the recommended oil grade and change interval, monitor oil level, ensure the cooling system is healthy, and inspect turbo hoses and clamps regularly for leaks. Proper fuel quality and octane are also important to minimize detonation risk.

Does Mopar extended protection help with 2.0L turbo problems?

Extended protection plans can cover turbo components, seals, and related failures after factory warranties lapse, depending on plan terms. Review coverage details with the provider to understand inclusions and exclusions.

Is the engine reliable long term?

Owner discussions describe reliability as mixed. The 2.0T can perform reliably with disciplined maintenance, but turbo life and engine wear are sensitive to cooling, oil quality, and fuel management. Expect normal wear patterns for a turbocharged inline‑4 in a midsize SUV over many miles.

Should I avoid low octane fuel?

Yes. While the engine is designed for a baseline octane, low octane can contribute to pre‑ignition risks and detonation in turbocharged operation. Use the manufacturer‑recommended octane and monitor for knocking or pinging signals.

What about piston failures?

Piston damage has been reported in some cases at moderate miles. If you hear unusual knocking or lose significant power under boost, seek immediate diagnostic testing. Address fuel quality, oil condition, and potential engine damage with a dealership or qualified shop.

How can I address carbon buildup effectively?

For significant deposits, cleaning methods such as walnut blasting are commonly used to restore intake valve cleanliness. Regular maintenance and using quality fuel help slow buildup over time.

Is there a difference in reliability between 2.0T and 3.6L engines?

Both engines show mixed reliability depending on use and maintenance. The 2.0T offers strong torque but can exhibit turbo‑related wear; the 3.6L V6 may feel less turbo‑related stress but has its own maintenance considerations. Evaluate based on your driving style and willingness to perform preventive maintenance.