Jeep Shuts Off While Driving And Won’t Start (Troubleshooting Guide)

A Jeep that suddenly shuts off while driving and then will not restart is one of the most alarming failures a driver can face. This guide explains the most common causes specific to Jeep models, how to diagnose each failure step by step, practical fixes you can attempt safely, and when to call a professional. Expect clear checks for electrical faults, fuel and ignition systems, and Jeep-specific components that commonly fail.

Quick summary

- Electrical faults are the leading cause of sudden shutdowns in many Jeep models. Check battery connections, chassis grounds, fuses, and the TIPM first. See the troubleshooting steps below.

- Bad ground straps and corroded connections are super common and cause flickering dash lights, loss of accessories, and no-start after stall. Clean and tighten all grounds.

- TIPM (Total Integrated Power Module) failures present as random electrical loss and no-start conditions. TIPM faults require professional diagnosis and often replacement or reprogramming.

- Ignition-sensing failures such as a bad crankshaft position sensor will kill the spark and stop the engine instantly and will prevent restart.

- Fuel delivery issues (fuel pump, relays, or clogged filter) can also cause a stall and no start. Prime the system and check pump operation.

- Perform a methodical checklist before accusing major parts: battery, terminals, grounds, fuses/relays, scanning for codes, then sensors and fuel.

- If the Jeep died in rain or wet conditions prioritize electrical checks first – moisture often exposes wiring and TIPM weaknesses.

How these failures commonly present

Typical signs when a Jeep dies while driving and then will not restart include:

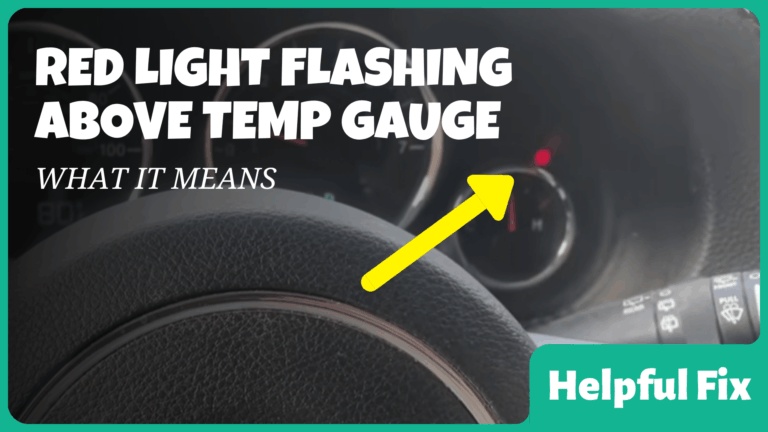

- Dash cluster lights flicker or go wild, then go dark

- Interior dome light or accessory lights flicker

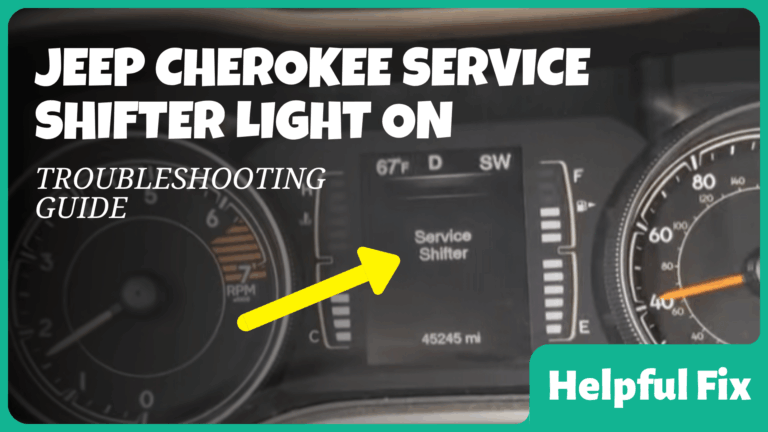

- No crank or no start, or accessories refuse to go to accessory or run positions

- Headlights or tail lights dim or flicker before the cut-out

- Transmission may fail to shift properly if electronics lose power

Several Jeep owners report these exact symptoms immediately before a dead-no-start event, often during wet weather. These real-world reports point strongly to electrical and grounding faults as prime suspects in many Jeep incidents documented on owner forums.

Electrical system: first line of inspection and repair

Because electrical failure is the most frequent root cause, start here and do not skip basic checks. The following steps are ordered from easiest to more involved.

1. Battery, terminals and cables

- Check battery voltage with a multimeter. Resting voltage should be about 12.4 to 12.7 V.

- Inspect terminals for corrosion, looseness, or crushed cables. Remove any corrosion, clean terminals, and tighten clamps.

- Replace severely corroded or swollen cables. Many no-starts are from poor cable contact even with a good battery.

2. Charging system (alternator)

- With the engine running (if you can start it) measure voltage across the battery. It should be about 13.5 to 14.5 V.

- A dead alternator can allow the engine to run until battery drains, then stall and refuse to restart.

3. Chassis grounds and engine grounds

Broken or corroded ground straps cause intermittent, severe symptoms. Clean and secure these points first. Owners and technicians repeatedly identify bad grounds as a top failure in Jeep models. Use a wire brush, tighten bolts, and ensure metal-to-metal contact. If a ground is hard to reach you may need angled wrenches or specialty tools to access bolts shown in repair walkthroughs.

4. Fuses, relays, and the TIPM

Check all under-hood fuse boxes and interior fuses. A blown fuse can cut fuel or ignition circuits. The TIPM is Jeep’s power distribution module that controls many electrical systems. When the TIPM malfunctions it can cause random shutdown or prevent the vehicle from entering accessory or start positions. Jeep owners and repair videos call out the TIPM as a frequent source of total electrical loss in model-specific diagnostics.

Ignition and engine management sensors

When the engine stops instantly and will not restart but the battery and wiring look fine, the engine control sensors are next.

Crankshaft position sensor (CKP)

- A failed CKP sensor will remove the spark signal and cause an immediate stall with no restart.

- Scan for codes. If codes point to CKP or cam position, replace the sensor and clear codes.

Ignition switch and immobilizer

- A faulty ignition switch or key transponder problem can prevent the vehicle from entering run or crank modes.

- Look for warning lights about security, or inability to access accessory mode. Swap keys if available to rule out a transponder issue.

General diagnostics for sensors: retrieve codes with an OBD-II scanner, monitor live data for crank and cam signals, then test sensor resistance and reference voltages per the service manual.

Fuel delivery: pump, relay and pressure checks

If the engine cranks but will not fire, treat fuel delivery next.

- Listen for the fuel pump prime for 2-3 seconds when the ignition is moved to run. No sound suggests pump failure or an open relay circuit.

- Check the fuel pump relay and fuse. Swap with a similar relay to test.

- Measure fuel pressure with a gauge at the Schrader valve. Compare to spec for your engine.

- Clogged filters or failed pump modules will cause stall under load and no restart until the system is repaired or primed.

Roadside troubleshooting: a safe, prioritized checklist

- Move to a safe location and put the vehicle in park with the hazard lights on.

- Check that the ignition is in the correct position and try a second key.

- Inspect battery terminals and engine/chassis ground bolts. Tighten and clean as needed.

- Scan for codes with a handheld OBD-II scanner. Note any P0xxx or U0xxx codes.

- Check fuses and relays in the under-hood power distribution module and interior fuse panel.

- Try to crank while a helper listens for fuel pump noise. If no pump sound, suspect fuel or TIPM power distribution.

- If the Jeep died in rain or wet conditions, dry connectors and grounds with compressed air and inspect for moisture intrusion.

Symptoms mapped to likely causes

| Symptom | Most likely cause | Quick test |

|---|---|---|

| Dash flicker then complete loss; no accessory or start | Ground strap, loose battery terminal, TIPM fault | Clean/tighten grounds and terminals, check fuses, scan for TIPM-related codes |

| Engine dies suddenly but cranks; no fire | Fuel pump or relay, fuel pressure loss | Listen for pump, check relay/fuse, measure fuel pressure |

| Engine dies and no crank or start; no spark | Crankshaft position sensor, ignition switch | Read OBD codes and monitor crank signal, test CKP sensor |

When to call a tow and what a shop will do

If you complete the basic electrical and fuel checks and the Jeep still will not start, tow it. Shops will perform:

- Full electrical diagnostic including TIPM testing and module resets

- OBD-II code analysis and live data capture

- Fuel pressure and pump current draw testing

- Sensor bench testing and replacement, including CKP or cam sensors

Expect diagnostic fees. TIPM replacement and programming can be expensive. Get a written estimate before work begins and ask whether the repair includes reprogramming and warranty for modules.

Prevention and maintenance to avoid recurrence

- Keep battery terminals and ground connections clean and tight. Inspect every 6 months.

- Address rusted fasteners and corroded wiring with dielectric grease and proper mechanical repairs.

- Replace failing batteries proactively. Batteries with low cranking amps cause erratic electrical effects.

- Service fuel filters and test the fuel pump at recommended intervals.

- Watch for intermittent symptoms – flickering lights or odd cluster behavior is a warning sign. Act before the vehicle dies on the road.

Frequently Asked Questions

Why did my Jeep die while driving and it will not even go to accessory?

When a Jeep refuses accessory or start after an in-motion shutdown the problem is usually an electrical distribution fault. Bad battery terminals, a failed TIPM or a major ground failure can cut power to the ignition and accessories, preventing the vehicle from entering accessory or run modes. Start with battery terminals and grounds, then check fuses and the TIPM reported by owners.

Can moisture or rain cause a Jeep to shut off and not restart?

Yes. Moisture can expose wiring faults, corroded grounds and failing module connectors. If the failure happened in rain, dry and inspect critical connectors, grounds and the TIPM area. Many owners see failures in wet conditions that reveal hidden corrosion or poor seals.

What role does the TIPM play in these failures?

The TIPM is the central power distribution module in many Jeeps and it controls relays and fuses for fuel, ignition and accessories. A TIPM fault can create the exact symptoms of total electrical loss and no-start. Professional diagnostics or TIPM replacement may be required when other checks fail as demonstrated in diagnostic videos.

How do I know if the crankshaft position sensor failed?

A failed CKP sensor typically causes an immediate stall with no restart and leaves no spark. An OBD-II scan may show codes like P0335 or related cam/crank codes. Testing requires measuring the sensor signal while cranking or replacing the sensor if data is inconclusive.

Is it safe to try to drive after the Jeep restarts?

Only if you have confirmed the failure was transient and performed basic repairs. If the cause was electrical or fuel related and not fully fixed, the vehicle can shut down again unpredictably. Tow the vehicle if you have any doubt about safety.

Can I reset the TIPM myself?

Simple resets can be attempted by disconnecting the battery for several minutes and reconnecting it, but this rarely fixes a genuine TIPM hardware fault. If the TIPM is suspected, have a shop test and reprogram modules as needed.

How much does TIPM replacement typically cost?

Costs vary by model and whether reprogramming is required. Expect diagnostic fees first. Replacement and programming can range widely. Get a written estimate and confirm whether the module is new, remanufactured or repaired, and whether it includes a warranty.

What tools should I carry to diagnose a no-start after a stall?

Carry a basic tool kit, a multimeter, a compact OBD-II scanner, a flashlight and dielectric grease. These will help you check battery voltage, grounds, fuses and read codes on the roadside.

Act methodically. Start with battery and grounds, then fuses and TIPM, next sensors and fuel. If you hit a wall, stop and get professional diagnostics. Do not drive a Jeep that shut off while moving until the root cause is confirmed and repaired.